销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

一、熔化炉类型:

本熔化炉为节电型产品、技术先进、控制精准可靠、制造工艺成熟、运行安全平稳、完善的保护系统、布局合理、管理维修方便。具有熔化速度快,能耗低,运行稳定可靠等特点。

二、本熔化炉组成范围:

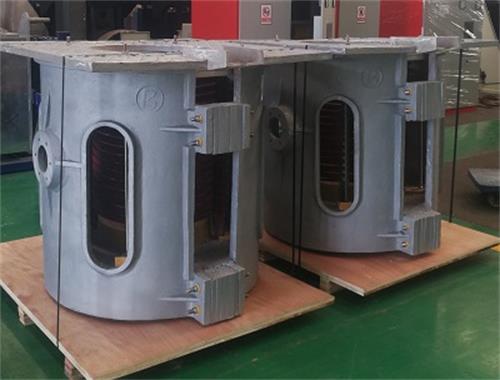

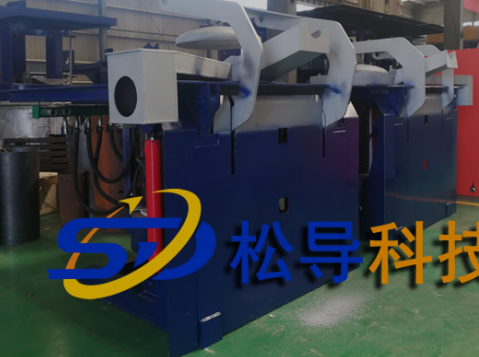

中频电源→电容器柜→炉体(钢壳或者铝壳炉体)→倾炉系统→远程控制箱→闭环冷却塔

熔化炉具有过电压、过电流、水温、水压、短路、接地等保护系统,操作面板上具有工作参数显示屏、显示工作状态的各个参数,并且有故障、温度等指示。

三、0.5T熔化炉技术参数

|

电源 |

工作形式:单供电6脉 |

|

整流形式:3相6脉 |

|

|

输出功率:250KW或者400KW ,功率不同价格不同。 |

|

|

电源效率≥98% |

|

|

启动方式:扫频软启动 |

|

|

启动率:100%(含重载) |

|

|

额定频率:500KHZ-1000KHZ |

|

|

交流电压:400V |

|

|

直流电压:500V |

|

|

中频电压:750V、1500V |

|

|

直流电流:500A-800A |

|

|

输入频率:50Hz |

|

|

循环水量:闭环水冷塔ZXZ-30T |

|

|

炉体 |

额定容量:500KG |

|

最大容量:600KG |

|

|

功率因数:≥0.92 |

|

|

熔化时间: 40分钟左右/炉 |

|

|

工作温度:1550℃-1700℃ |

|

|

装料直径:360mm(上口) 炉圈内径:560mm炉圈铜管为25x30x3mm |

|

|

钢壳:倾炉最大角度:95°铝壳:倾炉最大角度:180° |

|

|

出线方式:侧出线或者后出线 |

|

|

循环水量:闭环水冷塔ZXZ-30T |

|

|

倾炉方式:铝壳531减速机、钢壳液压 |

|

|

单位电耗:≤650度/T±5% 1550℃ |

|

|

变压器 |

额定容量:400KVA |

|

一次电压:10KV |

|

|

二次电压:400V、 575、660v |

|

|

一次相数:3相 |

|

|

二次相数:/3相6脉、6相12脉 |

|

|

输出形式:三△ 三Y |

|

|

冷却水 系统 |

闭环水冷塔ZXZ-30T |

|

冷却能力:150000 kcal/h 冷却水量:30m3/h 风机功率:1.1KWx2 风机风量 16800m3/h ×2 喷淋泵30m3/h;1.5kw 外形尺寸mm 2850×1250×2750(一体机尺寸) |

四、熔化炉配置表

|

序号 |

名 称 |

数量 |

备注 |

|

1 |

中频电源柜 |

1台 |

|

|

2 |

炉体 |

1套 |

钢壳、磁轭、 |

|

3 |

液压系统或者减速机 |

1台 |

液压泵站 |

|

4 |

外用操作台 |

1台 |

倾炉用外控制调功率 |

|

5 |

水冷电缆 |

1套 |

2根 |

|

6 |

坩埚模 |

1个 |

≥3mm钢板 |

|

7 |

整流变压器 |

1台 |

选配 |

|

8 |

PLC自动控制显示系统 |

1台 |

选配 |

|

9 |

闭环冷却塔 |

1台 |

选配 |

|

10 |

整流可控硅 |

2快 |

备用 |

|

11 |

逆变可控硅 |

2快 |

备用 |

First, the melting furnace type:

The melting furnace is a power-saving product, advanced technology, precise and reliable control, mature manufacturing process, safe and stable operation, perfect protection system, reasonable layout, convenient management and maintenance. It has the characteristics of fast melting speed , low energy consumption and stable and reliable operation.

Second, the melting furnace composition range:

Medium frequency power supply → capacitor cabinet → furnace body (steel shell or aluminum shell furnace body) → tilting furnace system → remote control box → closed loop cooling tower

The melting furnace has protection systems such as overvoltage, overcurrent, water temperature, water pressure, short circuit, grounding, etc. The operation panel has various parameters of the working parameter display screen and the display working state, and there are indications such as fault and temperature.

Third, 0.5T melting furnace technical parameters

|

power supply |

Working form: single power supply 6 pulses |

|

Rectified form: 3- phase 6- pulse |

|

|

Output power: 25 0KW or 400 KW , different power different prices. |

|

|

Power efficiency ≥98% |

|

|

Start mode: sweep soft start |

|

|

Startup rate: 100% (including heavy load) |

|

|

Rated frequency: 500KHZ-1000KHZ |

|

|

AC voltage: 400 V |

|

|

DC voltage: 500 V |

|

|

IF voltage: 750V, 1500V |

|

|

DC current: 500A-800 A |

|

|

Input frequency: 50Hz |

|

|

Circulating water volume: closed loop water cooling tower ZXZ-30T |

|

|

Furnace body |

Rated capacity: 500 KG |

|

Maximum capacity: 6 00KG |

|

|

Power factor: ≥ 0.9 2 |

|

|

Melting time : about 40 minutes / furnace |

|

|

Working temperature: 155 0°C -170 0°C |

|

|

Loading diameter: 360 mm (upper mouth) Inner diameter of the ring: 560mm ring copper tube is 25x30x3mm |

|

|

Steel: turndown maximum angle: 95 ° Aluminum Shell: turndown maximum angle: 180 ° |

|

|

Outlet mode: side outlet or rear outlet |

|

|

Circulating water volume: closed loop water cooling tower ZXZ-30T |

|

|

Tilting method: aluminum shell 531 reducer, steel shell hydraulic |

|

|

Unit power consumption: ≤ 65 0 degrees / T ± 5% 1550 ° C |

|

|

transformer |

Rated capacity: 400 KVA |

|

Primary voltage: 10KV |

|

|

Secondary voltage: 400 V , 575, 660v |

|

|

One phase: 3 phase |

|

|

Secondary phase number: /3 phase 6 pulse , 6 phase 12 pulse |

|

|

Output form: three △ three Y |

|

|

Cooling water system |

Closed - loop water cooling tower ZXZ-30T |

|

Cooling capacity : 1 5 0000 kcal/h Cooling water volume :30 m3/h Fan power : 1.1 KW x2 Fan air volume 16800m 3/h ×2 Spray pump 30 m3/h; 1.5 kw Dimensions mm 285 0× 1250 ×2750 (one size machine) |

Fourth , the melting furnace configuration table

|

Serial number |

Name |

Quantity |

Remarks |

|

1 |

IF power cabinet |

1 set |

|

|

2 |

Furnace body |

1 set |

Steel shell, yoke, |

|

3 |

Hydraulic system or reducer |

1 set |

Hydraulic power station |

|

4 |

External console |

1 set |

External control power adjustment for tilting furnace |

|

5 |

Water cooled cable |

1 set |

2 roots |

|

6 |

Model |

1 |

≥ 3 mm steel plate |

|

7 |

Rectifier transformer |

1 set |

Optional |

|

8 |

PLC automatic control display system |

1 set |

Optional |

|

9 |

Closed loop cooling tower |

1 set |

Optional |

|

10 |

Rectifier thyristor |

2 |

spare |

|

11 |

Inverter thyristor |

2 |

spare |

http://www.firstfurnace.com/BdwlkjProduct.asp?id=439

http://www.firstfurnace.com/BdwlkjProduct.asp?id=410

http://www.firstfurnace.com/BdwlkjProduct.asp?id=391

http://www.firstfurnace.com/BdwlkjProduct.asp?id=380

http://www.firstfurnace.com/BdwlkjProduct.asp?id=353

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Hydraulic_Steel_S/424.html

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Hydraulic_Steel_S/425.html

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Aluminum_shell_fu/426.html

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Aluminum_shell_fu/427.html

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Aluminum_shell_fu/428.html

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Aluminum_shell_fu/429.html

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Aluminum_shell_fu/430.html

http://www.tecfurnace.com/a/cpzx/Induction_melting_furnace/Aluminum_shell_fu/431.html

http://www.firstfurnace.com/BdwlkjProduct.asp?id=449

http://www.firstfurnace.com/BdwlkjProduct.asp?id=450

http://www.firstfurnace.com/BdwlkjProduct.asp?id=451

http://www.firstfurnace.com/BdwlkjProduct.asp?id=460

http://www.firstfurnace.com/BdwlkjProduct.asp?id=461

http://www.yxdianlu.com/BdwlkjProduct.asp?id=433

电 话:0379—69766926 手 机:13015583380