销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

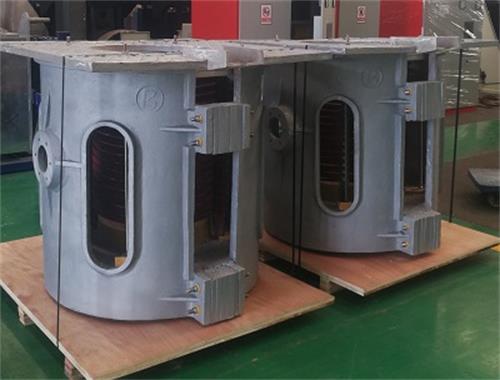

名称:0.25T中频熔炉

价格:0

一,用途:中频熔炉-铁水,钢水,铝水,铜液专用0.25T-60T中频熔炉。B,中频熔炼炉的基本组成 250kw 中频电源(并联逆变器),谐振电容器组,185mm 2水冷电缆,0.25T炉体(钢或铝壳)

C,250kw 中频电源的优点:功率输出恒定,熔化速度更快,节电效果更明显。将启动零电压扫描软件,该软件更适合频繁启动的要求。保护措施是全面的,例如过电流,过压,电流限制,压力限制,缺水和缺乏平等保护。在保证熔化速度的前提下,设备可靠。操作简单,适用于多种铸造工艺。

d,炉引入壳结构分为两种结构:铝壳炉和钢壳炉:该小容量炉壳一般是由铝合金制成,其具有结构合理,体积小,安装方便,维修简单和低维护的成本。大容量炉体壳体采用钢架结构,炉体结构由炉体固定架和炉体组成,炉体固定架和炉体采用整体骨架结构。

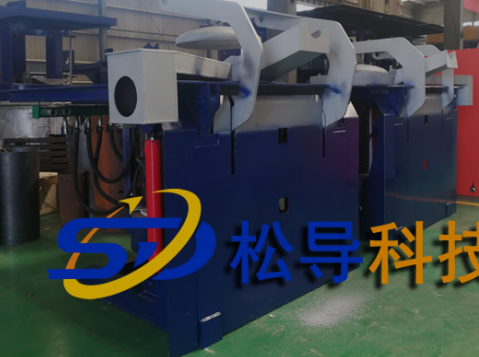

炉体的倾斜由液压系统控制,该液压系统是通过抬起炉体两侧的两个液压缸来实现的。炉体的复位是通过炉体自重产生的压力实现的。炉体有一个内置的轭铁,轭铁护罩可以减少漏磁通,防止炉体发热并提高效率。同时,轭架用作固定感应线圈的支撑件,从而炉体实现了高强度和低噪音。

轭是由冷轧硅钢板和不锈钢夹板制成的月牙形轭。铁芯与线圈的接合面是圆弧面,按压部是过去的线而不是线的面。好,漏磁少。堆叠硅钢板后,用专用夹板而不是专用螺纹螺钉将其拧紧。这种结构可以充分利用硅钢板的导磁面积并减少局部发热的可能性。G,线圈(感应线圈)的线圈是所述心脏的的中频熔化炉

。感应线圈在电流的作用下会产生强大的磁场,这会导致炉子中的金属产生涡流并产生热量。线圈是将电能转化为热量的关键,因此线圈的设计非常重要。该炉的线圈与中频熔炉的实际使用相结合 。根据电磁场原理,通过计算机专业软件的计算确定较好的解决方案,感应线圈的设计功率与实际运行功率之间的误差不大于5%,特别是线圈的绝缘性,匝间绝缘采用先进的绝缘方法进行保护,特殊的夹持技术可以有效降低线圈的轴向振动。感应线圈的内壁涂有进口的高温绝缘材料,并配有泄漏报警系统,可以有效地防止炉子磨损。可选的炉衬和顶出机构可以快速去除损坏的炉衬,并有助于快速建造炉子。

A, use:

Medium frequency melting furnace - molten iron, molten steel, molten aluminum, molten copper dedicated 0.25T-60T intermediate frequency melting furnace.

B, the basic composition of the intermediate frequency melting furnace

250kw intermediate frequency power supply (parallel inverter ), resonant capacitor bank, 185mm 2 water-cooled cable, 0.25T furnace body (steel or aluminum shell)

C, 250kw intermediate frequency power supply advantages:

Constant power output, faster melting speed and more obvious power saving effect.

Zero-voltage sweep software is started, which is more suitable for frequent start-up requirements.

The protection measures are comprehensive, such as overcurrent, overpressure, current limiting, pressure limiting, water shortage, and lack of equal protection. Under the premise of ensuring the melting speed, the equipment is reliable. Simple to operate, suitable for a variety of casting processes.

D, furnace introduction

The shell structure is divided into two structures: aluminum shell furnace and steel shell furnace :

The small-capacity furnace shell is generally made of aluminum alloy, which has reasonable structure, small volume, convenient installation, simple maintenance and low maintenance cost.

The large-capacity furnace body shell adopts a steel frame structure, and the furnace body structure is composed of a furnace fixing frame and a furnace body, and the furnace fixing frame and the furnace body adopt an integral skeleton structure. The tilting of the furnace body is controlled by the hydraulic system, which is realized by lifting two hydraulic cylinders on both sides of the furnace body. The resetting of the furnace body is realized by the pressure generated by the self-weight of the furnace body.

F, yoke

The furnace body has a built-in yoke, and the yoke shield can reduce the magnetic flux leakage, prevent the furnace body from heating and improve the efficiency. At the same time, the yoke acts as a support for fixing the induction coil, so that the furnace body achieves high strength and low noise. The yoke is a crescent-shaped yoke made of cold-rolled silicon steel sheet and stainless steel splint. The joint surface of the iron core and the coil is a circular arc surface, and the pressing portion is a surface instead of a line in the past. Good, less magnetic leakage. After the silicon steel sheets are stacked, they are tightened with a special splint instead of a special threaded screw. This structure can make full use of the magnetic conductive area of the silicon steel sheet and reduce the possibility of local heat generation.

G, coil (induction coil)

The coil is the heart of the intermediate frequency melting furnace . The induction coil generates a strong magnetic field under the action of current, which causes the metal in the furnace to generate eddy currents and generate heat. Coils are the key to converting electrical energy into heat, so the design of the coil is very important. The coil of the furnace is combined with the actual use of the intermediate frequency melting furnace . According to the principle of electromagnetic field, the better solution determined by the calculation of computer professional software, the error between the design power of the induction coil and the actual running power is not more than 5%, and the insulation of the coil In particular, the inter-turn insulation is protected by an advanced insulation method, and the special clamping technology can effectively reduce the axial vibration of the coil. The inner wall of the induction coil is coated with imported high-temperature insulation material, and is equipped with a leak alarm system, which can effectively prevent the furnace from being worn. Optional furnace lining and ejection mechanism can quickly remove the damaged lining and facilitate the rapid furnace construction.

http://www.songdaokeji.com/plus/view.php?aid=120

电 话:0379—69766926 手 机:13015583380