销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

名称:0.5T中频炉

价格:0

分类:0.5T中频炉根据逆变器电路的结构分为 0.5T并联中频炉 和 0.5T系列中频炉。

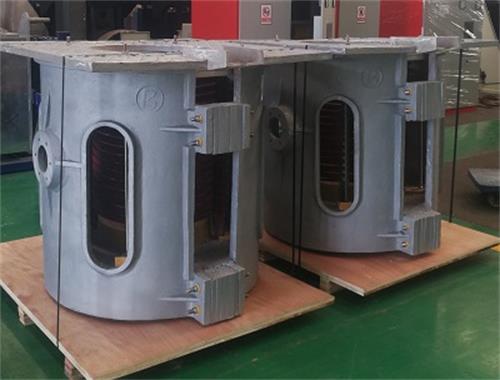

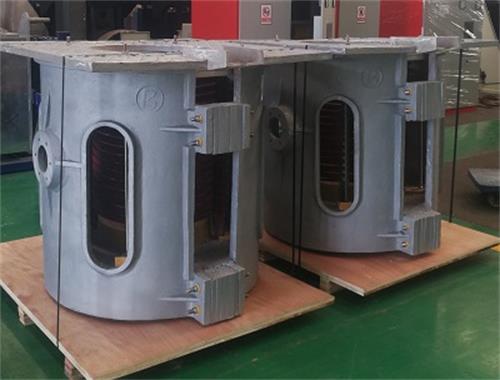

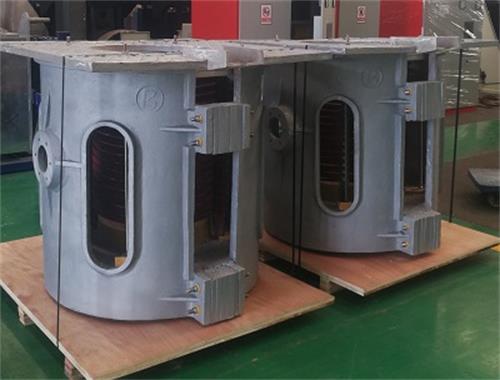

0.5T中频炉组成

0.5T中频炉,一个400kw 中频电源,两个0.5T钢壳或铝制炉,炉体上已安装钢轭。根据倾斜炉的不同,可以使用液压倾斜炉或机械倾斜炉(431减速器)。可选的整流变压器(ZS-500KVA),可选的完整水冷系统:闭环冷却塔(ZXZ-40T)。

B,钢壳本体

0.5T中频炉体包括钢壳炉体和 铝壳炉体 ,钢壳炉体包括炉壳,炉架,防尘罩,感应线圈,进出水管,分配器,轭,耐火材料形成块和感应线圈。防护涂层,液压倾斜缸,炉漏报警电极。感应线圈使用矩形的厚壁无氧铜管。

(1)一套带有钢质防护罩的倾斜式液压缸可保护缸杆免受灰尘和飞溅金属的侵害。每个气缸的进口端均装有一个节流阀,以防止在炉子倾斜时炉子突然掉落。

(2)在炉子底部安装由不锈钢线制成的接地/漏电探针。

(3)感应线圈的内表面涂有高铝线圈耐火涂层。

(4)炉衬耐火材料,包括炉衬,防尘罩(包括炉盖),炉具保护和铁锹首次用于建筑炉。

(5)感应线圈采用矩形厚壁无氧挤压铜管,强度高,载流量大。

(6),磁轭的厚度为(0. 23 mm)。定向硅钢片,通过特殊工艺制成,特殊弧形设计可以靠近设备。它占传感器面积的60-65%。

C,钢壳炉技术参数

|

序列号 |

项目 |

参数 |

|

1个 |

额定容量 |

0.5吨 |

|

2 |

感应环直径mm |

620 |

|

3 |

装载高度mm |

9 00 |

|

4 |

炉衬厚度mm |

90-120 |

|

5 |

额定工作温度°C |

1580 |

|

6 |

熔化速度(1550°C)t / h |

≥0.6T |

|

7 |

耗电量KWh / T |

620 |

D,液压站系统

(1),液压泵站,主要包括以下几个部分:

1,液压油箱

2,两台液压泵

3,两个电机

4,卸荷阀

5,截止阀

6,过滤器带状态指示

7,压力表

8,全套液压线

9,应急汽油机泵,用于紧急情况下清空炉内铁水。

购买中频炉,请先确定吨位大小,再确定功率大小。

参考资料:

1,中频炉的选择参考

2, 中频炉安全操作规程

3, 中频炉炼钢操作规程

4, 中频炉应急预案

5、0.5T中频炉技术参数

Classification: 0.5T intermediate frequency furnace is divided into 0.5T parallel intermediate frequency furnace and 0.5T series intermediate frequency furnace according to the structure of inverter circuit .

According to the structure of the furnace body: 0.5T aluminum shell intermediate frequency furnace and 0.5T steel shell intermediate frequency furnace

Composition of 0.5T intermediate frequency furnace

0.5T IF furnace, one 400kw medium frequency power supply, two 0.5T steel shell or aluminum furnace, the furnace body has installed steel yoke. Depending on the tilting furnace, a hydraulic tilting furnace or a mechanical tilting furnace (431 reducer) is available . Optional rectifier transformer (ZS-500KVA) , optional complete water cooling system : closed loop cooling tower (ZXZ-40T) .

B, steel shell body

The 0.5T intermediate frequency furnace body has a steel shell furnace body and an aluminum shell furnace body , and the steel shell furnace body includes a furnace shell, a furnace rack, a dust cover, an induction coil, an inlet and outlet water pipe, a distributor, a yoke, a refractory material forming block, and an induction coil. Protective coating, hydraulic tilting cylinder, leaking furnace alarm electrode. The induction coil uses a rectangular thick-walled oxygen-free copper tube.

(1) A set of tilting hydraulic cylinders with a steel protective cover protects the cylinder rod from dirt and splash metal. A throttle valve is installed at the inlet end of each cylinder to prevent the furnace from falling suddenly when the furnace is tilted.

(2) The grounding / leakage probe made of stainless steel wire is installed on the bottom of the furnace.

(3) The inner surface of the induction coil is coated with a high-aluminum coil refractory coating.

(4), lining refractory materials, including furnace lining, dust hood ( including furnace cover ) , furnace protection and steel shovel for the first time building furnace.

(5) The induction coil adopts a rectangular thick-walled oxygen-free extruded copper tube with high strength and large current carrying capacity.

(6), the yoke is ( 0. 23 mm ) thick . Oriented silicon steel sheet, made by special process, special arc design can be close to the device. It accounts for 60-65% of the sensor area .

C, steel shell furnace technical parameters

|

Serial number |

project |

parameter |

|

1 |

Rated Capacity |

0.5T |

|

2 |

Induction ring diameter mm |

620 |

|

3 |

Loading height mm |

9 00 |

|

4 |

Furnace lining thickness mm |

90-120 |

|

5 |

Rated operating temperature °C |

1580 |

|

6 |

Melting rate (1550 ° C) t / h |

≥ 0.6T |

|

7 |

Power consumption KWh/T |

620 |

D, hydraulic station system

(1), hydraulic pump station, mainly includes the following components:

1, hydraulic tank

2, two hydraulic pumps

3, two motors

4, an unloading valve

5, stop valve

6, the filter with status indication

7, a pressure gauge

8, a full set of hydraulic lines

9, emergency gasoline engine pump, used to empty the furnace molten iron in an emergency.

Buy the intermediate frequency furnace, please first determine the tonnage size, and then determine the power size.

Reference materials:

1 , the intermediate frequency furnace selection reference

2 , medium frequency furnace safety operation rules

3 , medium frequency furnace steelmaking operation procedures

4 , intermediate frequency furnace emergency plan

5, 0.5T intermediate frequency furnace technical parameters

电 话:0379—69766926 手 机:13015583380