销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

一、概况:

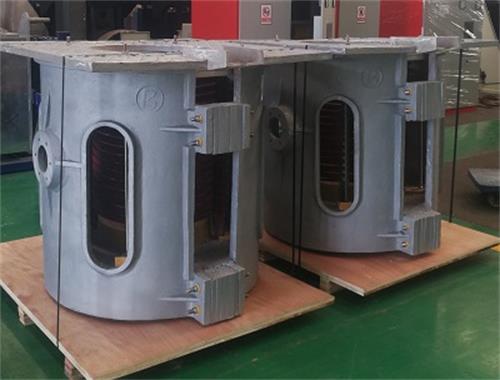

1.30吨熔钢炉说明

30吨熔钢炉:主要包括脉波整流变压器,一台中频电源、二台钢壳炉体和PLC辅助熔炼管理系统等组成。PLC辅助熔炼管理系统,不仅能够显示电源运行的实时数据与信息,还能够显示整个系统的运行状态与信息,并且具有自动烘炉,冷炉启动,故障诊断,故障信息显示和存储,运行信息显示,系统状态显示等功能。

基本配置:24脉波整流变压器(额定容量15000Kva),两台钢壳炉体、一套中频电源、一套逆变补偿电容,电源结构为12相24脉双整流并联逆变结构。倾炉方式为液压翻转,配远程操纵箱。

ZSSP-22000/10-1.5*4整流变压器的参数:

|

电炉容量(t) |

中频电源功率(KW) |

变压器容量(KVA) |

电压组合 |

连接组标号 |

阻抗电压(%) |

|

|

一次侧(KV) |

二次侧(V) |

|||||

|

30T |

20000 |

22000 |

10 |

1500 |

Y/d11 |

6~8 |

二、30T/20000kw中频无芯感应熔炼炉主要技术参数

|

A、综合参数 |

|||||||

|

序号 |

项目 |

参数要求 |

|||||

|

1 |

30吨熔钢炉形式 |

中频熔炼炉 |

|||||

|

2 |

30吨熔钢炉用途 |

用于熔炼铸铁、碳钢等 |

|||||

|

3 |

额定容量 |

30T |

|||||

|

4 |

最大容量 |

30T+10% |

|||||

|

5 |

工作温度 |

1700℃ |

|||||

|

6 |

冶炼材质 |

铸铁、碳钢 |

|||||

|

7 |

下出料方式 |

液压:液压控制 |

|||||

|

9 |

工作噪声 |

<85分贝 |

|||||

|

10 |

炉体结构 |

钢壳 |

|||||

|

12 |

熔化率 |

30T/h |

|||||

|

13 |

熔化电耗 |

≤520±5% kW.h/t铸铁 |

|||||

|

≤550±5% kW.h/铸钢 |

|||||||

|

14 |

熔化时间 |

100分钟/炉 |

|||||

|

B、电气参数: |

|||||||

|

序号 |

项目 |

参数 |

|||||

|

1 |

电源功率 |

20000kw / 12相24脉30T |

|||||

|

2 |

整流项数 |

24脉 |

|||||

|

3 |

逆变器 |

SCR并联逆变 |

|||||

|

4 |

额定频率 |

250Hz |

|||||

|

5 |

进线交流电压 |

1500V |

|||||

|

6 |

中频电压 |

3000V |

|||||

|

7 |

启动成功率 |

100% |

|||||

|

8 |

功率因数 |

大于0.95 |

|||||

|

10 |

中频电源 |

循环水流量 |

m3/h |

120 |

|||

|

进水温度 |

℃ |

≯35 |

|||||

|

温升 |

℃ |

≯15 |

|||||

|

压力 |

Mpa |

0.2-0.3 |

|||||

|

炉体(挖水池) |

循环水流量 |

m3/h |

220 |

||||

|

进水温度 |

℃ |

≯40 |

|||||

|

温升 |

℃ |

≯20 |

|||||

|

压力 |

Mpa |

0.25-0.3 |

|||||

|

C、炉体指标 |

|||||||

|

序号 |

项目 |

40吨 |

|||||

|

1 |

炉壳结构 |

钢壳或者铝壳 |

|||||

|

2 |

炉壳材质 |

45#钢 |

|||||

|

3 |

面板厚度 |

加厚增加强度20mm |

|||||

|

4 |

磁轭材质 |

Z11-0.3 |

|||||

|

5 |

磁轭覆盖率 |

85% |

|||||

|

6 |

磁轭夹紧 |

不锈钢 1Cr18Ni9 |

|||||

|

7 |

磁轭散热方式 |

双水冷 |

|||||

|

8 |

感应器铜管材质 |

T2纯铜99.9 |

|||||

|

9 |

感应器铜管规格 |

壁厚≥8mm总量大于5吨 |

|||||

|

10 |

感应器匝数 |

主匝22圈,上下各3圈水冷圈 |

|||||

|

11 |

感应器绝缘 |

3道浸漆,双层包扎,耐压8000V |

|||||

|

|

感应器绕制 |

加长形双并绕,机器绕制(非手工绕制) |

|||||

|

|

感应圈高度 |

2000mm x2875mm |

|||||

|

12 |

水路 |

16进16出、水路连接软管 |

|||||

|

13 |

出线方式 |

测出线 |

|||||

|

14 |

水冷圈材质 |

紫铜管 |

|||||

|

15 |

炉壳发热量 |

<75℃(炉底与炉盖除外) |

|||||

|

16 |

绝缘 |

线圈与磁轭绝缘采用云母板双层隔离 |

|||||

|

17 |

耐火胶泥 |

GROUT 563A美国-天津联矿产品 |

|||||

|

18 |

螺栓 |

普通碳钢螺栓为8.8级。其他螺栓不锈钢材质或铜制 |

|||||

|

19 |

坩埚模厚度 |

>5mm |

|||||

|

20 |

水路连接软管 |

采用无阻燃高绝缘橡胶管 |

|||||

|

21 |

集水器 |

不锈钢材质 |

|||||

|

1 |

液压泵 |

双泵双电 |

|||||

|

2 |

机组型式 |

立式 |

|||||

|

3 |

液压元件 |

榆次或国产名牌 |

|||||

|

4 |

保证倾炉角度 |

0~95° |

|||||

30 tons medium frequency induction melting furnace

1. Description of 30 tons of molten steel furnace

30 tons of molten steel furnace: including pulse rectifier transformer, a frequency power supply, two sets of steel melting furnace and auxiliary PLC management systems and other components. The PLC-assisted smelting management system not only displays the real-time data and information of the power supply operation, but also displays the operating status and information of the entire system, and has automatic oven, cold furnace start, fault diagnosis, fault information display and storage, and operation information display. , system status display and other functions.

Basic configuration: 24-pulse rectifier transformer (rated capacity 15000KVA), two sets of steel furnace, a frequency power supply, a set of inverters compensation capacitor structure 12 with power supply 24 double pulserectifier inverter parallel structure. The tilting method is hydraulically reversed with a remote control box.

Parameters of ZSSP- 22000/ 10-1.5*4 rectifier transformer:

|

Electric furnace capacity (t) |

IF power (KW) |

Transformer capacity (KVA) |

Voltage combination |

Connection group label |

Impedance voltage (%) |

|

|

Primary side (KV) |

Secondary side (V) |

|||||

|

30T |

20 000 |

22000 |

10 |

1500 |

Y/d11 |

6-8 |

2 , 30T / 20000kw intermediate frequency coreless induction melting furnace main technical parameters

|

project |

Parameter requirement |

|||

|

30 tons of molten steel furnace form |

Medium frequency melting furnace |

|||

|

30 tons of molten steel furnace use |

Used for melting cast iron , carbon steel, etc. |

|||

|

Rated Capacity |

30T |

|||

|

Maximum capacity |

30T + 1 0% |

|||

|

Operating temperature |

1700 °C |

|||

|

Smelting material |

Cast iron , carbon steel |

|||

|

Lower discharge mode |

Hydraulic : hydraulic control |

|||

|

Working noise |

<85 decibels |

|||

|

Furnace structure |

Steel shell |

|||

|

Melting rate |

30 T/h |

|||

|

Melting power consumption |

≤ 52 0±5% kW.h/t cast iron |

|||

|

≤ 55 0±5% kW.h/ cast steel |

||||

|

Melting time |

100 minutes / furnace |

|||

|

project |

parameter |

|||

|

Power supply |

20000kw / 12 phase 24 pulse 30T |

|||

|

Number of rectifiers |

24 veins |

|||

|

Inverter |

SCR parallel inverter |

|||

|

Rated frequency |

250 Hz |

|||

|

Incoming AC voltage |

1500 V |

|||

|

IF voltage |

3000 V |

|||

|

Start success rate |

100% |

|||

|

Power factor |

Greater than 0.9 5 |

|||

|

Intermediate frequency power supply |

Circulating water flow |

m 3 /h |

120 |

|

|

Inlet temperature |

°C |

≯35 |

||

|

|

Furnace (dig the pool) |

Temperature rise |

°C |

≯15 |

|

pressure |

Mpa |

0.2-0.3 |

||

|

Circulating water flow |

m 3 /h |

220 |

||

|

Inlet temperature |

°C |

≯40 |

||

|

Temperature rise |

°C |

≯20 |

||

|

pressure |

Mpa |

0.25-0.3 |

||

|

C, furnace index |

||||

|

Serial number |

project |

40 tons |

||

|

1 |

Furnace shell structure |

Steel or aluminum |

||

|

2 |

Furnace shell material |

45 # steel |

||

|

3 |

Panel thickness |

Thickening increase strength 20 mm |

||

|

4 |

Yoke material |

Z11-0. 3 |

||

|

5 |

Yoke coverage |

8 5% |

||

|

6 |

Yoke clamping |

Stainless steel 1Cr18Ni9 |

||

|

7 |

Yoke cooling method |

Double water cooling |

||

|

8 |

Sensor copper tube material |

T2 pure copper 99.9 |

||

|

9 |

Inductor copper tube specifications |

The total wall thickness ≥ 8mm is more than 5 tons |

||

|

10 |

Sensor turns |

Main 匝 22 laps, 3 rounds of water cooling ring |

||

|

11 |

Inductor insulation |

3-way dipping paint, double-layer dressing, pressure resistance 8000V |

||

|

|

Sensor winding |

Long and double winding, machine winding (not hand-wound) |

||

|

|

Induction loop height |

2000mm x2875mm |

||

|

12 |

waterway |

16 in 16 out , water connection hose |

||

|

13 |

Way out |

Measure line |

||

|

14 |

Water cooling ring material |

Copper tube |

||

|

Furnace shell heat |

<75 ° C (except the furnace bottom and the furnace cover) |

|||

|

insulation |

The coil and the yoke are insulated by a double layer of mica board. |

|||

|

Refractory clay |

GROUT 563A US-Tianjin Union Products |

|||

|

bolt |

Ordinary carbon steel bolts are grade 8.8. Other bolts made of stainless steel or copper |

|||

|

Die thickness |

>5mm |

|||

|

Water connection hose |

Use non-flame retardant high insulation rubber tube |

|||

|

Water collector |

Stainless steel |

|||

|

Hydraulic pump |

Double pump double |

|||

|

Unit type |

Vertical |

|||

|

Hydraulic Components |

Yuci or domestic famous brand |

|||

|

Guaranteed angle of the furnace |

0 to 95° |

|||

http://www.firstfurnace.com/BdwlkjProduct.asp?id=389

电 话:0379—69766926 手 机:13015583380