销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

一、概述

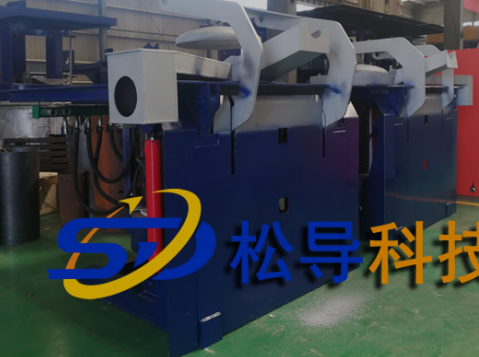

全自动中频感应加热成套设备,具有振动排序、托辊进料、温度自动控制、三位温控分检功能

本套设备主要用于圆钢、钢管的整体透热。加热炉体采用快速更换方式,当更换产品规格时只须更换炉体即可。更换炉体只需几分钟的时间

二、按照单件重量最大计算,加热时间来计算功率

三、 设备范围与功能描述:

1.设备范围见下表

|

序号 |

内容 |

数量 |

备注 |

||

|

1 |

整流变压器 |

1台 |

选配用户自购 |

||

|

2 |

晶闸管串联逆变中频电源 |

1套 |

|

||

|

3 |

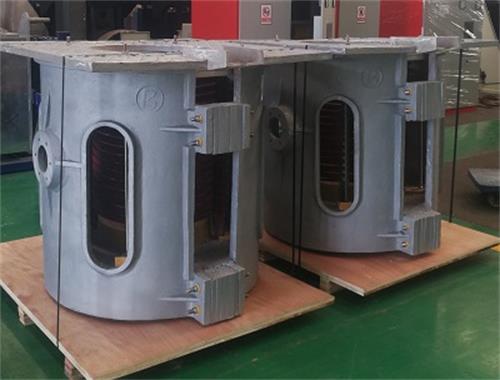

感应加热器 |

1套 |

包括水冷导轨 |

||

|

3.1 |

GTR80(适用料φ75) |

1套 |

|

||

|

4 |

感应加热炉台架 |

1套 |

|

||

|

5 |

上料平台及缓冲链传送装置 |

1套 |

|

||

|

6 |

上料机 |

1台 |

|

||

|

7 |

托辊送料机 |

1台 |

|

||

|

8 |

夹辊进料机 |

1台 |

|

||

|

9 |

退料装置 |

1套 |

退料钢筒,上料机 |

||

|

10 |

快速出料机 |

1台 |

|

||

|

11 |

三位分检机 |

1台 |

|

||

|

12 |

温控系统(红外线测温和控制仪) |

1套 |

PLC中央控制台 |

||

|

12.1 |

PLC中央控制台 |

1套 |

|

||

|

12.2 |

工控软件 (MCGS系统) |

1套 |

|

||

|

12.3 |

可编程控制器 |

1套 |

|

||

|

12.4 |

液晶屏 |

1套 |

|

||

|

12.5 |

双比色红外测温仪(西安瑞光) |

1台 |

|

||

|

12.6 |

光电报警开关 |

1套 |

|

||

|

12.7 |

控制柜 |

1台 |

|

||

|

12.8 |

操作台 |

1台 |

|

||

|

10 |

冷却水系统 |

1套 |

用户自购 |

||

|

A、综合参数 |

||

|

序号 |

项目 |

参数要求 |

|

1 |

电源功率 |

60KW-3000KW |

|

2 |

整流项数 |

6脉 |

|

3 |

逆变器 |

SCR逆变 |

|

4 |

额定频率 |

1KHZ-8KHZ |

|

5 |

进线电压 |

380V |

|

6 |

中频电压 |

1600V |

|

7 |

启动成功率 |

100% |

|

8 |

功率因数 |

大于0.92 |

|

9 |

出口加热温度 |

1150℃ |

|

10 |

加热电耗 |

≤340±5% kW.h/t |

|

|

|

|

|

B、热交换冷却水系统参数 |

||

|

序号 |

项目 |

参数 |

|

1 |

进水压力 |

0.2-0.4MPa |

|

2 |

进水温度 |

5-35℃ |

|

3 |

出水温度 |

<55℃ |

1. Overview

Fully automatic medium frequency induction heating complete equipment with vibration sequencing, idler feeding, automatic temperature control and three-level temperature control

This set of equipment is mainly used for the overall heat transfer of round steel and steel pipes . The heating furnace body adopts the quick replacement method, and only the furnace body needs to be replaced when the product specifications are replaced. It takes only a few minutes to replace the furnace

2, according to the maximum weight of a single piece, the heating time to calculate the power

3, Device range and function description:

1. Equipment range is shown in the table below

|

Serial number |

content |

Quantity |

Remarks |

|

|

1 |

Rectifier transformer |

1 set |

Optional user purchase |

|

|

2 |

Thyristor series inverter IF power supply |

1 set |

|

|

|

3 |

Induction heater |

1 set |

Includes water cooled rails |

|

|

3.1 |

GTR 80 (applicable material φ 75 ) |

1 set |

|

|

|

4 |

Induction heating furnace stand |

1 set |

|

|

|

5 |

Feeding platform and buffer chain conveyor |

1 set |

|

|

|

6 |

Feeder |

1 set |

|

|

|

7 |

Roller feeder |

1 set |

|

|

|

8 |

Pinch roller feeder |

1 set |

|

|

|

9 |

Material return device |

1 set |

Return steel cylinder, loading machine |

|

|

10 |

Quick discharge machine |

1 set |

|

|

|

11 |

Three sorting machines |

1 set |

|

|

|

12 |

Temperature control system (infrared temperature measurement and control instrument) |

1 set |

PLC center console |

|

|

12 .1 |

PLC center console |

1 set |

|

|

|

12 .2 |

Industrial control software (MCGS system) |

1 set |

|

|

|

12 .3 |

Programmable Controllers |

1 set |

|

|

|

12 .4 |

LCD screen |

1 set |

|

|

|

12 .5 |

Double colorimetric infrared thermometer (Xi'an Ruiguang) |

1 set |

|

|

|

12 .6 |

Photoelectric alarm switch |

1 set |

|

|

|

12 .7 |

Control cabinet |

1 set |

|

|

|

12 .8 |

Console |

1 set |

|

|

|

10 |

Cooling water system |

1 set |

User-purchased |

|

http://www.firstfurnace.com/BdwlkjProduct.asp?id=378

http://www.firstfurnace.com/BdwlkjProduct.asp?id=398

电 话:0379—69766926 手 机:13015583380