销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

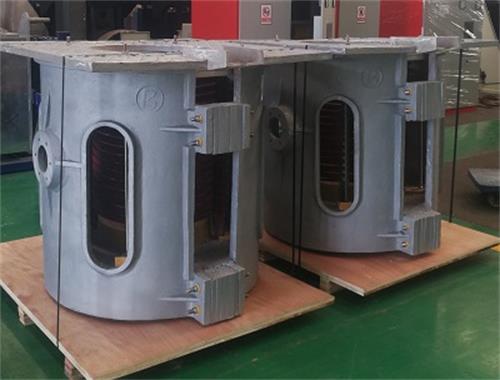

1. Description of 30 tons of molten steel furnace

30 tons of molten steel furnace: including pulse rectifier transformer, a frequency power supply, two sets of steel melting furnace and auxiliary PLC management systems and other components. The PLC-assisted smelting management system not only displays the real-time data and information of the power supply operation, but also displays the operating status and information of the entire system, and has automatic oven, cold furnace start, fault diagnosis, fault information display and storage, and operation information display. , system status display and other functions.

Basic configuration: 24-pulse rectifier transformer (rated capacity 15000KVA), two sets of steel furnace, a frequency power supply, a set of inverters compensation capacitor structure 12 with power supply 24 double pulserectifier inverter parallel structure. The tilting method is hydraulically reversed with a remote control box.

Parameters of ZSSP- 22000/ 10-1.5*4 rectifier transformer:

|

Electric furnace capacity (t) |

IF power (KW) |

Transformer capacity (KVA) |

Voltage combination |

Connection group label |

Impedance voltage (%) |

|

|

Primary side (KV) |

Secondary side (V) |

|||||

|

30T |

20 000 |

22000 |

10 |

1500 |

Y/d11 |

6-8 |

2 , 30T / 20000kw intermediate frequency coreless induction melting furnace main technical parameters

|

project |

Parameter requirement |

|||

|

30 tons of molten steel furnace form |

Medium frequency melting furnace |

|||

|

30 tons of molten steel furnace use |

Used for melting cast iron , carbon steel, etc. |

|||

|

Rated Capacity |

30T |

|||

|

Maximum capacity |

30T + 1 0% |

|||

|

Operating temperature |

1700 °C |

|||

|

Smelting material |

Cast iron , carbon steel |

|||

|

Lower discharge mode |

Hydraulic : hydraulic control |

|||

|

Working noise |

<85 decibels |

|||

|

Furnace structure |

Steel shell |

|||

|

Melting rate |

30 T/h |

|||

|

Melting power consumption |

≤ 52 0±5% kW.h/t cast iron |

|||

|

≤ 55 0±5% kW.h/ cast steel |

||||

|

Melting time |

100 minutes / furnace |

|||

|

project |

parameter |

|||

|

Power supply |

20000kw / 12 phase 24 pulse 30T |

|||

|

Number of rectifiers |

24 veins |

|||

|

Inverter |

SCR parallel inverter |

|||

|

Rated frequency |

250 Hz |

|||

|

Incoming AC voltage |

1500 V |

|||

|

IF voltage |

3000 V |

|||

|

Start success rate |

100% |

|||

|

Power factor |

Greater than 0.9 5 |

|||

|

Intermediate frequency power supply |

Circulating water flow |

m 3 /h |

120 |

|

|

Inlet temperature |

°C |

≯35 |

||

|

|

Furnace (dig the pool) |

Temperature rise |

°C |

≯15 |

|

pressure |

Mpa |

0.2-0.3 |

||

|

Circulating water flow |

m 3 /h |

220 |

||

|

Inlet temperature |

°C |

≯40 |

||

|

Temperature rise |

°C |

≯20 |

||

|

pressure |

Mpa |

0.25-0.3 |

||

|

C, furnace index |

||||

|

Serial number |

project |

40 tons |

||

|

1 |

Furnace shell structure |

Steel or aluminum |

||

|

2 |

Furnace shell material |

45 # steel |

||

|

3 |

Panel thickness |

Thickening increase strength 20 mm |

||

|

4 |

Yoke material |

Z11-0. 3 |

||

|

5 |

Yoke coverage |

8 5% |

||

|

6 |

Yoke clamping |

Stainless steel 1Cr18Ni9 |

||

|

7 |

Yoke cooling method |

Double water cooling |

||

|

8 |

Sensor copper tube material |

T2 pure copper 99.9 |

||

|

9 |

Inductor copper tube specifications |

The total wall thickness ≥ 8mm is more than 5 tons |

||

|

10 |

Sensor turns |

Main 匝 22 laps, 3 rounds of water cooling ring |

||

|

11 |

Inductor insulation |

3-way dipping paint, double-layer dressing, pressure resistance 8000V |

||

|

|

Sensor winding |

Long and double winding, machine winding (not hand-wound) |

||

|

|

Induction loop height |

2000mm x2875mm |

||

|

12 |

waterway |

16 in 16 out , water connection hose |

||

|

13 |

Way out |

Measure line |

||

|

14 |

Water cooling ring material |

Copper tube |

||

|

Furnace shell heat |

<75 ° C (except the furnace bottom and the furnace cover) |

|||

|

insulation |

The coil and the yoke are insulated by a double layer of mica board. |

|||

|

Refractory clay |

GROUT 563A US-Tianjin Union Products |

|||

|

bolt |

Ordinary carbon steel bolts are grade 8.8. Other bolts made of stainless steel or copper |

|||

|

Die thickness |

>5mm |

|||

|

Water connection hose |

Use non-flame retardant high insulation rubber tube |

|||

|

Water collector |

Stainless steel |

|||

|

Hydraulic pump |

Double pump double |

|||

|

Unit type |

Vertical |

|||

|

Hydraulic Components |

Yuci or domestic famous brand |

|||

|

Guaranteed angle of the furnace |

0 to 95° |

|||

http://www.firstfurnace.com/BdwlkjProduct.asp?id=389

电 话:0379—69766926 手 机:13015583380