销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

名称:中频钨钼烧结炉

价格:0

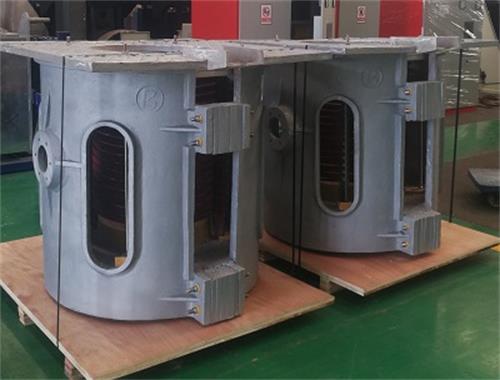

中频钨钼烧结炉主要由晶闸管中频电源,氢保护高温烧结炉炉体,温度自动控制系统,机械泵真空系统,立式下负荷系统,各种保护作用系统,喷涂钨加热体,保温材料组成等。

1. 中频加热部分由 KGPS-750 / 1.0 750KW 1.0KHz 电源柜,电热电容器柜,连接铜排和发动机机构组成;

2 ,烧结炉由槽,感应器,氧化铝,氧化锆绝缘材料,钨坩埚,开放式回流槽,氢气 / 氮气控制箱,龙门,下部装载机构和卸料轨,真空系统等组成;

3. 自动控制系统由三部分组成:自动温度控制系统,气体控制系统和自动运动控制。温度自动控制系统 测量 由 Wre5-26 热电偶和光纤传感器,由温度调节器控制,并且通过一个无纸记录器记录。气体控制系统和机械运动自动控制部分由PLC 集中控制 。整个控制系统都安装在垂直或台式控制台上进行控制。

中频钨钼烧结炉主要技术指标

主要用于超大型钨钼产品的烧结。要求:长期运行稳定,可靠,安全且耗电。设计结构,材料选择,电气配置,安全措施和程序控制是合理且先进的。

内径:Φ 内 960 × 1900 × 22

内部氦气材料:钨

烧结最高温度: 2350 ° C

工作温度: 2300 ° Ç

电源电压: 380V , 50Hz ,三相四线制

工作频率: 1000Hz

电源:≤ 750KW

自动温度控制,测量,显示,自动记录

炉内气体保护,流量可调,出口处排渣

平均温度区:不小于 1650 毫米 的高度方向;

温度均匀性:炉中心温度差在1 0 ℃以内 ,用热电偶测得 17 00 ℃ 。2300 ° C纯钨产品的密度差 不超过 0.20 g / cm3 。

炉型:立式,底装。最大电荷大小 ≥ ˚F 880 * 1850毫米,最大重量 8 吨工件;

温度控制精度:± 1 ° C

真空系统

真空系统由 ZX-70 机械泵, ZJP-300 罗茨泵, GD-J160 挡板阀, DDC-JQ80 电磁阀和框架,电气控制,管道,真空计,波纹管等组成。抽至 10Pa 少于 30 分钟。

Overview

Medium frequency tungsten-molybdenum sintering furnace mainly consists of thyristor intermediate frequency power supply, hydrogen protection high temperature sintering furnace body, temperature automatic control system, mechanical pump vacuum system, vertical lower loading system, various protection and action systems, spraying tungsten heating body, heat preservation Composition of materials and so on.

1. The intermediate frequency heating part consists of KGPS-750/1.0 750KW 1.0KHz power supply cabinet, electric heating capacitor cabinet, connecting copper bars and engine mechanism;

2 , the sintering furnace consists of tank, inductor, alumina, zirconia insulation material, tungsten crucible, open return tank, hydrogen / nitrogen gas control box, gantry, lower loading mechanism and removal rail, vacuum system, etc. composition;

3. The automatic control system consists of three parts: automatic temperature control system, gas control system and automatic movement control. The temperature automatic control system is measured by Wre5-26 thermocouple and fiber optic sensor, controlled by a temperature regulator, and recorded by a paperless recorder. The gas control system and the mechanical movement automatic control part are centrally controlled by the PLC . The entire control system is mounted on a vertical or bench-top console for control.

Main technical indicators of medium frequency tungsten-molybdenum sintering furnace

Mainly used for the sintering of extra large tungsten and molybdenum products. Requirements: Long-term operation is stable, reliable, safe, and power-consuming. The design structure, material selection, electrical configuration, safety measures, and program control are reasonable and advanced.

Inner diameter: Φ within 960 × 1900 × 22

Internal helium material: tungsten

Sintering maximum temperature: 2350 °C

Working temperature: 2300 °C

Power supply voltage: 380V , 50Hz , three-phase four-wire system

Working frequency: 1000Hz

Power supply: ≤ 750KW

Automatic temperature control, measurement, display, automatic recording

Gas protection in the furnace, adjustable flow, and slag discharge at the outlet

the average temperature zone: not less than 1650 mm in the height direction ;

Temperature uniformity: the furnace center, the temperature difference of within 1 0 ℃, when measured by a thermocouple 17 00 ℃. The density difference of 2300 °C pure tungsten products is not more than 0.20 g / cm3 .

furnace type: vertical, bottom loading. The maximum charge size ≥ f 880 * 1850mm, the maximum weight of 8 tons workpiece;

temperature control accuracy: ± 1 °C

vacuum system

The vacuum system consists of ZX-70 mechanical pump, ZJP-300 Roots pump, GD-J160 baffle valve, DDC-JQ80 solenoid valve and frame, electric control, pipeline, vacuum gauge, bellows and so on. Pump to 10Pa for less than 30 minutes.

http://www.songdaokeji.com/plus/view.php?aid=310

电 话:0379—69766926 手 机:13015583380