销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

名称:中频感应烧结炉

价格:0

一, 工作原理

通过使用电磁感应原理,将强电流引入感应线圈,以在交变磁场中在电荷内部产生感应电流,从而将电荷加热到感应加热装置。

B,设备组成

1. 中频电源 KGPS-160KW-2.5KHz

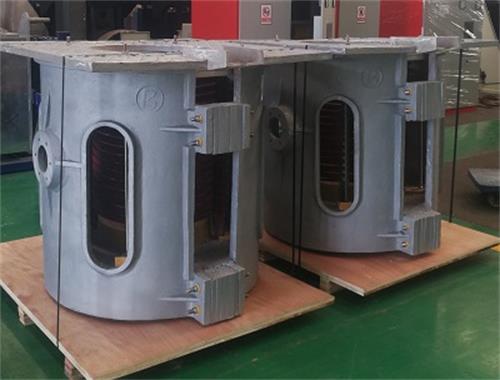

2. 水冷炉体

注意:水冷式炉体分为内缸和外缸,它们由整块钢板制成。内缸体由不锈钢制成,外缸体材料为 Q235 。喷头由标准喷头制成,内喷头为不锈钢,外喷头为 Q235 。制造方法和要求均符合GB150-89 的规定

3. 温度控制系统和外部操作柜 。

4. 工作平台(两侧都有楼梯) 。

5. 抽真空系统

C 。 主要技术指标和功能

1. 工作温度: 2300 °C

2. 加热体材质:钨

3. 加热体尺寸 Φ370mm (内径) h = 700mm

4. 中频电源

(1 )电源电压: 380v; 50HZ; 三相四线

(2 )最大输出功率: 160KW

(3) 最大输出电压: 750V

(4) 最大工作频率: 2500Hz

5. 温度使用两个独立的温度测量系统,包括 Wre5-26 热电偶和非接触式光纤传感温度计 。

6. 采用氢气保护,流量可调,氢气出口设有排渣口 。

C ,安全保护功能

1. 具有过流,过压,缺相,冷却水压力保护不足等问题。

2. 具有过热保护功能。

3. 具有断电报警功能。

4. 具有氢防爆功能。

D ,供水系统

1. 水质参数。

水压 ≥0.2-0.4Mpa。

出水温度< 55 °C

进水温度< 5-35 °C

硬度 CaO < 10mg 当量

酸-碱 的pH = 7-8.5

悬浮固体< 10mg / L

耐水性> 2.5K Ω

铁含量< 2mg

2. 游泳池数量

由总功率乘以 4-0.05 取 。 如果空间有限,当水箱体积较小时,可以增加冷却塔。如果数量可以保证,最好在长江以南增加一个冷却塔。长江以北地区,可能没有适当考虑。

3. 升降机

它应该是 游泳池到设备的距离的1.5 倍。

4. 水流量

将总功率乘以 0.04 。

参考文章:

A, working principle

By using the principle of electromagnetic induction, a strong current is introduced into the induction coil to generate an induction current inside the charge in the alternating magnetic field, thereby heating the charge to an induction heating device.

B,Equipment composition

1. Medium frequency power supply KGPS-160KW-2.5KHz

2. Water-cooled furnace body

Note: The water-cooled furnace body is divided into inner and outer cylinders, which are made of a whole piece of steel plate. The inner cylinder body is made of stainless steel, and the outer cylinder material is Q235 . The head is made of standard head, the inner head is stainless steel, and the outer head is Q235 . The manufacturing methods and requirements are all in accordance with the provisions of GB150-89

3. Temperature control system and external operation cabinet .

4. Work platform (with stairs on both sides) .

5. Pre-vacuum system

C . The main technical indicators and functions

1. Working temperature: 2300 °C

2. Heating body material: tungsten

3. Heating body size Φ 370mm (inside diameter) h=700mm

4. Intermediate frequency power supply

(1 ) Power supply voltage: 380v; 50HZ; three-phase four-wire

(2 ) Maximum output power: 160KW

(3) Maximum output voltage: 750V

(4) Maximum operating frequency: 2500Hz

5. The temperature uses two independent temperature measurement systems consisting of Wre5-26 thermocouple and non-contact optical fiber sensing thermometer .

6. It adopts hydrogen protection, the flow rate is adjustable, and the hydrogen outlet is provided with slag discharge port .

C , security protection function

1. It has over-current, over-pressure, phase loss, and insufficient cooling water pressure protection.

2. With over temperature protection.

3. With power failure alarm function.

4. With hydrogen explosion-proof function.

D , water supply system

1. Water quality parameters.

Water pressure ≥ 0.2-0.4Mpa.

Effluent temperature < 55 °C

Inlet water temperature < 5-35 °C

Hardness CaO < 10mg equivalent

Acid-base ph = 7-8.5

Suspended solids < 10mg/L

Water resistance > 2.5K Ω

Iron containing < 2mg

2. Pool volume

Multiplied by the total power 4-0.05 take . If space is limited, when the small tank volume, can be added cooling towers. When the volume can be guaranteed, it is better to add a cooling tower to the south of the Yangtze River. North of the Yangtze River, may not be considered properly.

3. Water lift

It should be 1.5 times the distance from the pool to the equipment .

4. Water flow

Multiply the total power by 0.04 .

Reference article:

Method of using medium frequency induction sintering furnace

http://www.songdaokeji.com/plus/view.php?aid=286

电 话:0379—69766926 手 机:13015583380