销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

工艺要求

工件:Φ20-Φ32×10m

涂层要求:环氧粉末喷涂400-500um

工艺线速度:3-4m/分钟

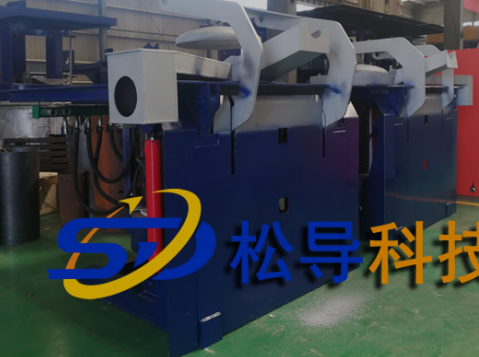

涂覆线;

传动线全长40米,包含8个4.0米×0.8米传动架;底座和传动轮支架全部采用10#槽钢焊接。还配有4个单架(其中有一个配耐高温轮胎),方便追管和脱管。

传动动力共有4个,全部采用变频调速,变频器采用丹麦丹佛斯公司技术的海利普变频器。变频调速使钢管传输平稳,从而使防腐层厚度均匀。我们还采用一种压管机构,能防止管道在追管和脱管加速时对正在加工管道的影响。

传动轮采用充气轮胎(因工件小轻,充气轮胎变形能力强),传动轴连接。减速机采用摆针式减速机。涂覆线总长40米。

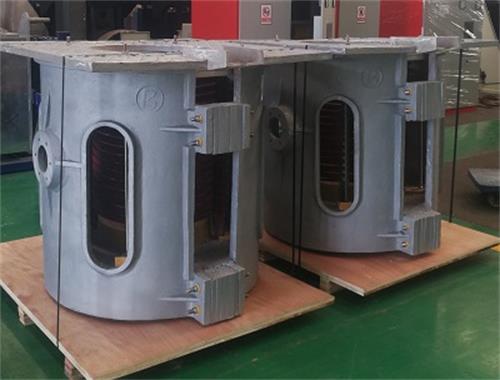

中频感应加热设备:KGPS-250/1

静电喷涂设备:

1、4枪控制中心DK型

以上装置含自动喷枪4支,喷枪为内置高压,控制柜控制4支自动喷枪的电压、电流及气路系统,并控制支文丘里供粉泵供粉系统。

以上装置含流化床供粉系统1套,流化床外形尺寸:(L×W×H)800×775×570(mm)含4支文丘里供粉泵。

拨管系统:

上下管拨叉4个,气缸4个及控制系统。(包括电磁阀、阀块、PVC气管、控制按钮等)。

Φ 20 — Φ 32 sucker rod epoxy spraying production line

Process requirements

Work piece: Φ 20- Φ 32 × 10m

Coating requirements: epoxy powder coating 400-500um

Process line speed: 3-4m/ min

Coating line

Transmission line length of 40 m, containing eight 4.0 m × 0.8 yards gear frame; bracket base and the drive wheel 10 in all channel # welding. There are also 4 single racks (one of which is equipped with high temperature resistant tires) for easy chasing and pipe removal.

There are 4 transmission powers , all of which adopt frequency conversion speed regulation. The frequency converter adopts Hailipu frequency converter of Danfoss Technology of Denmark. The frequency conversion speed regulation makes the steel pipe transmission smooth, so that the thickness of the anti-corrosion layer is uniform. We also use a pressure tube mechanism that prevents the pipe from affecting the pipe being machined during acceleration and decoupling.

The drive wheel uses pneumatic tires (due to the small light weight of the work-piece, the deformation ability of the pneumatic tire is strong), and the drive shaft is connected. The reducer uses a pendulum type reducer. The coating line has a total length of 40meters.

Medium frequency induction heating equipment: KGPS-250/1

Electrostatic spraying equipment:

4 gun control center DK type:The above device includes 4 automatic spray guns , the spray gun is built-in high pressure, the control cabinet controls the voltage, current and gas path system of 4 automatic spray guns, and controls the powder supply system of the Venturi powder supply pump.

The above device contains one set of fluidized bed powder supply system . The size of the fluidized bed : (L × W × H) 800 × 775 × 570 (mm) contains 4 venturi powder supply pumps.

Pipe system:

Upper and lower fork tube 4, a cylinder 4 and a control system. (including solenoid valves, valve blocks, PVC gas pipes, control buttons, etc.).

http://www.songdaofurnace.com/a/cpzx/pipe_induction_heat_treatment/390.html

电 话:0379—69766926 手 机:13015583380